这是一款乐泰公司推出的EDGEBOND用的UV型产品,关于EDGEBOND的文章之前探讨过一篇,参看《关于Edgebond Adhesive的应用》,这个是zymet推出的一款热固化系列的产品。其实个人觉得EDGEBOND应该是CORNERBOND的另一种说法,如果要做严格区分的话前者胶水是基本不会渗透到BGA或者元件底部的,而早期的CORNERBOND产品是有直接点在BGA四角或元件底部四角的(这类工艺有一定的隐患,膨胀系数太大时会导致锡球焊接不良),但绝大多数是在焊接完之后再去施胶固化补强的。当时在几大notebook代工厂都有用到这个工艺,但有些是选取的热固化环氧系列的,有些是选取UV固化的,两个体系各有利弊,看客户权衡选择了。几年前曾送过一款环氧胶水给其中一家大公司进行了测试,他们出具的报告我也觉得是接触到的电子厂商中最为专业的报告之一。

闲话少说,回到正题,贴出这个产品的技术资料,后面有TDS&MSDS&ROHS的PDF资料供大家下载。 不过这个ROHS可不是汉高公司送检SGS之类的报告,只不过是他们的一份自我声明,貌似世界级胶商都是不做ROHS或类似的报告的,这个一般要由代理商承担的。 另外这份资料里面也出现了一个明显矛盾的错误,呵呵! 在使用指南中写到”Product is shipped at 2 to 8ºC with ice packs to prevent excessive temperature exposure during shipping.”,指产品的储运需要冷藏(刚看到这里时我还纳闷了一把,很少会见到UV胶需要冷藏储运的,一般都是要求避光,是不是这款胶有什么特别之处呢?),再看到后面“.Optimal Storage: 8 to 28°C. Storage below 8°C or greater than 28°C can adversely affect product properties”,估计前面那段话是写错了,这个才是比较标准的UV胶储存条件。

PRODUCT DESCRIPTION

3705 provides the following product characteristics:

|

3705 UV cure adhesive is designed for high throughput assembly operations. Its thixotropic nature reduces migration of the liquid product after application to the substrate.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Viscosity, Brookfield – HBT, 25 °C, mPa·s (cP):

Spindle TB, Helipath, speed 10 rpm 44,000

Specific Gravity @ 25 °C 1.1

Flash Point – See MSDS

TYPICAL CURING PERFORMANCE

Recommended UV Cure

Light Source and Condition: Zeta 7411 UV Flood System

Light Intensity, mW/cm² 30

UV Wavelength, nm 365

Time, seconds 80

3705 can be cured by exposure to UV and/or visible light of sufficient intensity. Cure rate and ultimate depth of cure depend on light intensity, spectral distribution of light source, exposure time, etc.

Fixture Time

UV fixture time is defined as the light exposure time required to develop a shear strength of 0.1 N/mm² .

UV Fixture Time , Glass microscope slides, 0 gap, seconds:

6 mW/cm² , measured @ 365 nm ≤10

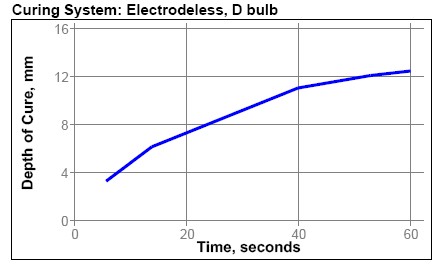

Depth of Cure

Cure depth depends both on external factors including the type of light source, light intensity and exposure time and on internal factors including composition of the adhesive

The following graph show the increase in depth of cure with time as measured from the thickness of the cured product formed in a 15mm diameter PTFE die.

TYPICAL PROPERTIES OF CURED MATERIAL

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion , ASTM E831-86, µm/m/K:

| alpha 1 |

66 |

| alpha 2 |

151 |

| alpha 3 |

217 |

Glass Transition Temperature, ASTM D 1640, °C:|

Tg 1 -39

Tg 2 77

Thermal Conductivity, ASTM E1530, W/mK 0.17

Elongation , ASTM D882,% 186

Tensile Modulus , ASTM D882 N/mm² 175 (psi) (25,381)

Tensile Strength, ASTM D882 N/mm² 15.6 (psi) (2,262)

Electrical Properties:

Dielectric Constant , ASTM D150:

@ 100Hz 4.584

@ 1KHz 4.799

@ 10KHz 4.633

@ 100KHz 4.221

@ 1MHz 4.312

@ 100Hz 0.0319

@ 1KHz 0.0222

@ 10KHz 0.0189

@ 100KHz 0.02

@ 1MHz 0.0343

Volume Resistivity @ 100 volts, ohms-cm 1.13×1017

Surface Resistivity100 volts, ohms 1.53×1016

TYPICAL PERFORMANCE OF CURED MATERIAL

Shear Strength:

Block Shear Strength, ASTM 700:

Polycarbonate to Polycarbonate N/mm² 12.56 (psi) (1,822)

GENERAL INFORMATION

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

DIRECTIONS FOR USE

1. Product is shipped at 2 to 8ºC with ice packs to prevent excessive temperature exposure during shipping.

2. This product is light sensitive; exposure to daylight, UV light and artificial lighting should be kept to a minimum during storage and handling.

3. The product should be dispensed from application with black feedlines.

4. For best performance bond surfaces should be clean and free from grease.

5. Apply adhesive to one of the bond surfaces and assemble immediately.

6. Cure rate is dependent on lamp intensity, distance from light source, depth of cure needed or bondline gap and light transmission of the substrate through which the radiation must pass.

7. Cooling should be provided for temperature sensitive substrates such as thermoplastics.

8. Crystalline and semi-crystalline thermoplastics should be checked for risk of stress cracking when exposed to liquid adhesive.

9. Excess uncured adhesive can be wiped away with organic solvent (e.g. Acetone).

10. Bonds should be allowed to cool before subjecting to any service loads.

Not for product specifications

The technical data contained herein are intended as reference only. Please contact your local quality department for assistance and recommendations on specifications for this product.

Storage

Store product in the unopened container in a dry location. Storage information may be indicated on the product container labeling.Optimal Storage: 8 to 28°C. Storage below 8°C or greater than 28°C can adversely affect product properties.Material removed from containers may be contaminated during use. Do not return product to the original container. Henkel Corporation cannot assume responsibility for product which has been contaminated or stored under conditions other than those previously indicated. If additional information is required, please contact your local Technical Service Center or Customer Service Representative.

Not for product specifications

The technical data contained herein are intended as reference only. Please contact your local quality department for assistance and recommendations on specifications for this product.

Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

华为网盘下载:http://dl.dbank.com/c0gfdb0b62

注册本地下载:

LOCTITE EDGEBOND UV 3705 TDS&MSDS&ROHS (117.2 KB, 9 次)

LOCTITE EDGEBOND UV 3705 TDS&MSDS&ROHS (117.2 KB, 9 次)

您没有权限下载此文件。

《【扒一扒】日本高纯球形硅微粉材料生产商》: 作为一种无机非金属矿物功能性粉体材料,硅微粉广泛应用于电子材料、电工绝缘材料、胶黏剂、特种陶瓷、精密铸造、油漆涂料、油墨、硅橡胶等领域。 目前,世界上只有中国、日本、韩国、美国等少数国家具备硅微粉生产能力... 全文 ?