PRODUCT DESCRIPTION

3874™ provides the following product characteristics:

Technology Acrylic

Chemical Type Acrylic ester

Appearance (uncured) Light grey opaque fluid , No visible bubbles. Slight separation of filler acceptableLMS

Components One component – requires no mixing

Viscosity High, thixotropic

Cure Activator

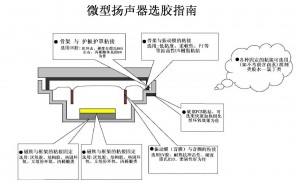

Application Bonding

3874™ is a thermally conductive adhesive. When used with Activator 7387™, it cures rapidly to form a high strength, high modulus, thermoset acrylic polymer. Typical applications include bonding heat sinks to heat dissipating components such as BGAs in electronics applications. The thixotropic nature of 3874™ reduces the migration of liquid product after application to the substrate.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity@ 25 °C 2.08

Flash Point – See MSDS

Viscosity, Brookfield – HBT, 25 °C, mPa·s (cP):

Spindle TB, speed 0.5 rpm, Helipath 800,000 to 1,800,000LMS

Spindle TB, speed 5 rpm, Helipath 200,000 to 450,000LMS

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph below shows the shear strength developed with time on grit blasted steel lap shears and tested according to ISO 4587. (Activator 7387™ applied to one surface).

TYPICAL PROPERTIES OF CURED MATERIAL

Cured for 24 hours @ 70 °C, followed by 7 days @ 22 °C

Physical Properties:

Coefficient of Thermal Expansion, ISO 11359-2, K-1 76×10-6

Coefficient of Thermal Conductivity, ISO 8302, W/(m·K) 1.25

Glass Transition Temperature, °C 49 Shore Hardness, ISO 868, Durometer D 72

Elongation, at break, ISO 37, % 3.2

Initial @ 22 °C.

Electrical Properties:

Volume Resistivity, IEC 60093, Ω·cm 4.3×1014

Surface Resistivity, IEC 60093, Ω 3.8×1014

Dielectric Breakdown Strength, IEC 60243-1, kV/mm 23.6

After 1 week @ 85 °C / 85% RH

Electrical Properties:

Volume Resistivity, IEC 60093, Ω·cm 1.5×1014

Surface Resistivity, IEC 60093, Ω 2.6×1013

Dielectric Breakdown Strength, IEC 60243-1, kV/mm 3.5

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 °C, Activator 7387™ on 1 side Lap Shear Strength, ISO 4587: Steel N/mm² ≥11.7LMS

(psi) (≥1,695)

Aluminum N/mm² ≥7LMS (psi) (≥1,015)

GENERAL INFORMATION

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials For safe handling information on this product, consult the Material Safety Data Sheet (MSDS).

Directions for use:

1. For best performance bond surfaces should be clean and free from grease.

2. Apply Activator 7387™ to one of the bond surfaces and the adhesive to the other surface. Parts should be assembled immediately..

3. Excess adhesive can be wiped away with organic solvent.

4. Bond should be held clamped until adhesive has fixtured.

5. Product should be allowed to develop full strength before subjecting to any service loads (typically 24 to 72 hours after assembly, depending on bond gap, materials and ambient conditions).

Loctite Material SpecificationLMS

LMS dated March-07, 2003. Test reports for each batch are available for the indicated properties. LMS test reports include selected QC test parameters considered appropriate to specifications for customer use. Additionally, comprehensive controls are in place to assure product quality and consistency. Special customer specification requirements may be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location. Storage information may be indicated on the product container labeling. Optimal Storage: 2 °C to 8 °C. Storage below 2 °C or greater than 8 °C can adversely affect product properties. Material removed from containers may be contaminated during use. Do not return product to the original container. Henkel Corporation cannot assume responsibility for product which has been contaminated or stored under conditions other than those previously indicated. If additional information is required, please contact your local Technical Service Center or Customer Service Representative.

loctite 3874 TDS (59.7 KB, 193 次)

loctite 3874 TDS (59.7 KB, 193 次)

《【扒一扒】日本高纯球形硅微粉材料生产商》: 作为一种无机非金属矿物功能性粉体材料,硅微粉广泛应用于电子材料、电工绝缘材料、胶黏剂、特种陶瓷、精密铸造、油漆涂料、油墨、硅橡胶等领域。 目前,世界上只有中国、日本、韩国、美国等少数国家具备硅微粉生产能力... 全文 ?